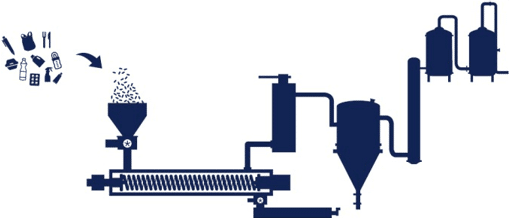

Wastemy offers an innovative solution for the local recovery of plastic, using a technological process of pyrolysis at low temperature (around 500 ° C) with the possible addition of biomass.

This process makes it possible to energetically densify the raw material and thus to obtain a gas and a liquid with high energy values.

The refining of these two effluents at the pyrolysis outlet allows the extraction of valuable chemicals (ethylene, propylene and aromatics), which are the building blocks of the chemical industry (plastics, cosmetics, solvents, etc.). The remaining liquid can be upgraded as fuel (diesel and gasoline), while the gases can be used on site for the production of the energy required for pyrolysis.

Ethylene & Propylene

Paraffin & Aromatic

Diesel gas

Gas

Wastemy technology makes it possible to treat different plastics, which until now were difficult to recycle, in the same pyrolysis.

Unlike current recovery solutions which favor high temperature and mainly gas yields, our technology makes it possible to establish the most suitable separation schemes according to the local context.

The advantages of our technology:

The use of biomass in optimal proportions → increases the yields and the quality of the products.

A tailor-made artificial intelligence for optimal control of process parameters and proposals for optimized liquids and solids.

The ability to carry out efficient pyrolysis at low temperature: A reduced energy impact and better yields: More condensed matter recovered (liquid / solid)

Thanks to our technology, several refining scenarios can be defined according to the desired end products. Some scenarios may be compatible with each other. This will mainly involve the production of automotive fuels and / or chemicals.

Scenario 1

Obtaining fuels (gasoline, diesel) from pyrolysis oils

Scenario 2

Obtaining fuels and materials from composites (carbon fibers for example)

Scenario 3

Obtaining styrene monomer, BTX / BTEX and aliphatic gasoline.